From supply chain bottlenecks to misdeclared cargo, there are a number of forces currently at play in the cargo insurance marketplace. We sat down with Jencap’s Inland Marine Brokers and VP of Falvey Insurance Group Will Frohne to dig in and unpack these trends.

1. Delays in cargo movement and port accumulation.

Throughout the COVID-19 pandemic, we saw a lot of port accumulation, with cargo coming in but not being transported out quickly. Factory and port closures due to the pandemic put a great deal of strain on the supply chain and created a shipping bottleneck, which left ships just waiting to be unloaded.

As the oft-repeated saying amongst cargo insurance professionals goes, “cargo at rest is cargo at risk.” Cargo left sitting for long periods of time is always at risk of any number of perils—theft and fire, in particular. “As a result,” Frohne notes, “we saw quite a spike in static exposures at the ports.”

Although port congestion has improved since the height of the pandemic, we still haven’t worked through all of the supply chain issues and delays. Now, even after cargo is unloaded, driver shortages increase the delays in moving products along to their destination.

2. Warehouse stockpiling and “just in case” inventory.

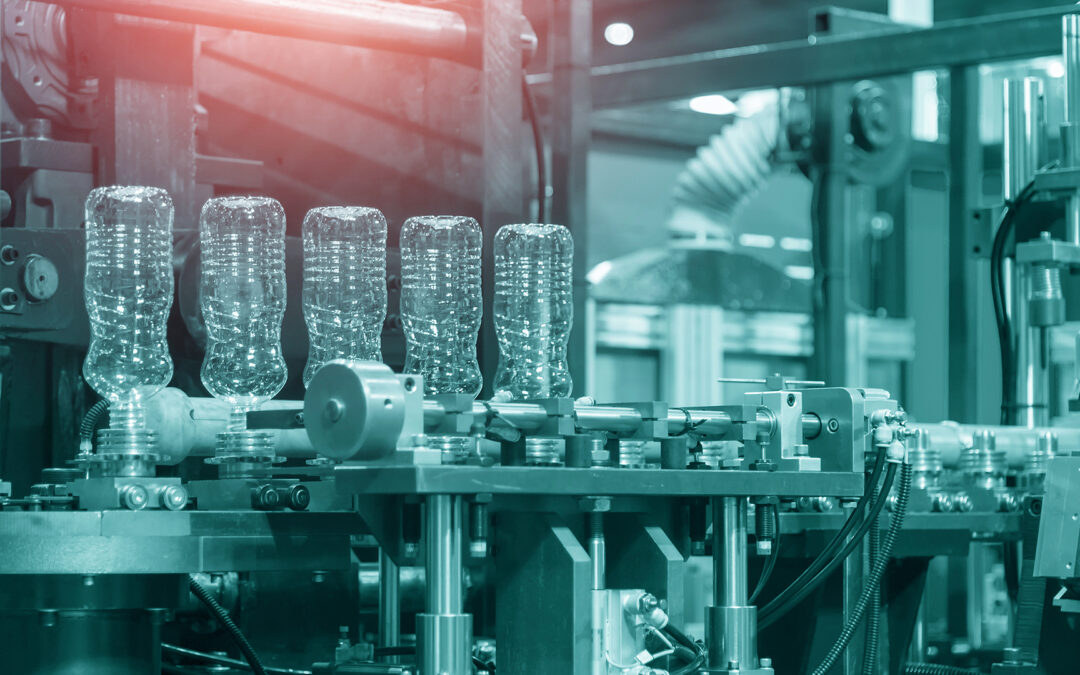

Thanks to supply chain delays during the pandemic, a lot of retailers weren’t able to get goods to their customers in a timely fashion. As a result, many moved away from a “just in time” shipping model to a “just in case” inventory model. Rather than manufacturing and shipping products on demand, companies began stockpiling goods so they’d always have products on hand and ready to ship.

What these companies couldn’t anticipate, however, were the current economic conditions that have prompted consumers to reign in their buying habits. People are tightening up their budgets and simply aren’t buying as much as they once were. As a result, there’s a decrease in product demand, leaving a lot of excess inventory stored in warehouses. “This is creating a bigger exposure on the static side of things,” says Frohne.

Now, instead of goods sitting in ports, they’re sitting in warehouses. This is where our marine brokers are picking up coverage on the stock side of stock throughput coverage.

3. Inflation and the rising value of warehoused inventory.

In addition to more products being stored for longer amounts of time in warehouses, the value of those products is rising. With the current inflation rate of 4.93%, that aggregate increase in value can have a profound impact on insurance and how much actual capacity is provided per location or per warehouse.

4. Increases in vessel sizes and maximizing cargo space.

With an eye toward efficiency and profitability, companies want to put as much as they can on a ship. In an effort to move more products more quickly, companies are building larger ships that can accommodate more shipping containers in a single voyage. In addition, ships are also stacking containers higher than in the past. The higher the container stack, the less stable it becomes, and the more likely they are to topple over during inclement weather or in rough waters.

According to Frohne, “We’ve seen quite a spike in the number of containers lost at sea in the last few years than we ever did before, because of the size of the vessels.” There’s also been an increase in frequency and severity of extreme weather events, which exacerbates this issue.

Weather aside, higher container stacks can lead to other problems during transit. For instance, fires on board are harder to combat on larger ships that are packed to capacity. If there’s a fire in a container below deck and that container is at the bottom of a stack, it’s hard to reach quickly. By the time someone gets to the fire, there’s already been significant damage.

5. Misdeclared or undeclared cargo.

Although companies are supposed to disclose if their cargo contains dangerous or hazardous materials, that doesn’t always happen. Some shippers fail to declare or inaccurately declare dangerous materials to avoid paying higher freight charges. It’s estimated that roughly 150,000 container time-bombs carry misdeclared goods worldwide. This is particularly alarming because dangerous goods can ignite fires and explosions and release pollutants into the marine environment.

“Think about how these containers are moved,” says Frohne. “They go from one conveyance, either a rail or a truck, with a crane. Then they get picked up and put onto a vessel. There’s a lot of banging and things get knocked around.” If dangerous or hazardous cargo that gets damaged or somehow gets wet during all of that moving around, it can be a recipe for disaster.

Jencap’s team of ocean and inland marine experts stay on the forefront of all emerging marketplace trends. As your wholesale partner, we’ll work alongside you to find the protection your clients’ need for their goods and merchandise, regardless of whether their shipments are sitting on a ship at sea, on a shelf in a warehouse, or being transported to their final destination. Learn more about Jencap’s expansive marine capabilities and speak to an expert from our team today.